X-Ray Equipment Disposal in Australia

ToggleNeed Compliant X Ray Disposal in Australia?

Ensure your X-ray equipment is disposed of legally, safely, and with full documentation. Our certified medical equipment recycling solutions are trusted by hospitals, clinics, and laboratories nationwide.

Explore X Ray Disposal ServicesX Ray Disposal in Australia: Legal, Safe, and Compliant Guide (2026)

X ray disposal in Australia is a highly regulated process that sits at the intersection of radiation safety, environmental protection, and legal compliance. Hospitals, clinics, dental practices, veterinary centres, and laboratories cannot treat the disposal of X-ray machines like ordinary electronic waste. Improper handling can expose staff and the public to radiation risks, contaminate the environment with hazardous materials, and result in serious regulatory penalties.

In 2026, x ray disposal requirements in Australia are stricter than ever. National guidance from ARPANSA, combined with state-based radiation and EPA laws, makes it clear that every x ray machine disposal must follow a documented, approved, and traceable pathway. This guide explains exactly how to approach x ray equipment disposal the right way, with clear explanations for Victoria, New South Wales, and Queensland.

What X-Ray Disposal Is and Why It's Important

The regulated decommissioning, disassembly, recycling, or destruction of equipment that generates ionizing radiation is referred to as X-ray disposal. Fluoroscopy systems, mobile radiography units, dental X-ray machines, diagnostic X-ray machines, and some lab imaging equipment fall under this category.

The disposal of x-ray equipment presents special risks in contrast to regular e-waste. High-voltage parts, lead shielding, beryllium windows, PCB-contaminated lubricants, and other dangerous materials may be present in X-ray equipment even when they are turned off. For this reason, the disposal of x-ray machines is governed differently from the recycling of regular electronic trash.

Violations of x-ray disposal regulations may result in fines, license suspension, injury to one's reputation, and environmental damage. Patients, employees, waste handlers, and the larger community are all protected by proper disposal.

Regulatory Framework for X Ray Disposal in Australia (2026)

At a national level, x ray disposal is governed by the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA). Under the ARPANS Act, X-ray machines are classified as controlled apparatus because they are capable of producing ionising radiation.

ARPANSA requires that the disposal of x ray machines must ensure the equipment is rendered permanently inoperable. This means the unit cannot be repaired or reactivated without specialised expertise and replacement of critical components. In many cases, prior approval or formal notification is required before disposal.

National standards are then enforced through state and territory legislation. While the core principles are consistent across Australia, each state has its own reporting and licensing requirements for x ray equipment disposal.

X Ray Disposal in Victoria

If you are wondering how to dispose of x ray equipment in Victoria, the process is governed by the Radiation Act 2005 and overseen by the Victorian Department of Health.

In Victoria, licence holders must notify the regulator when an X-ray machine is disposed of. The disposal of x ray equipment must ensure that the radiation-producing components are destroyed or permanently disabled. Lead shielding and hazardous materials must be handled in accordance with EPA Victoria requirements, often classified as Prescribed Industrial Waste.

Facilities in Melbourne and regional Victoria commonly use licensed medical equipment recyclers to manage x ray disposal safely and legally.

Disposing of X Rays in NSW

Disposing of x rays in NSW falls under the Protection from Harmful Radiation Act 1990 and the oversight of the NSW EPA and NSW Health.

In most cases, the disposal of x ray machines in NSW is permitted under a general consent, provided the equipment is rendered permanently inoperable and the regulator is notified. This includes disabling the X-ray tube, cutting high-voltage cables, and removing radiation signage.

Organisations must never sell or transfer an operational X-ray machine without approval. NSW authorities take illegal disposal or untracked transfers very seriously.

How to Dispose of X Rays in QLD

For businesses asking how to dispose of x rays in QLD, the Radiation Safety Act 1999 and Radiation Safety Regulation 2021 apply.

Queensland explicitly requires that an X-ray unit must be incapable of being repaired and incapable of producing radiation before disposal. Disposal notifications must usually be submitted within seven days. This makes x ray machine disposal in Queensland one of the more strictly enforced processes in Australia.

Step-by-Step Process for X Ray Machine Disposal

X ray disposal should always follow a structured process.

Engage Qualified Personnel

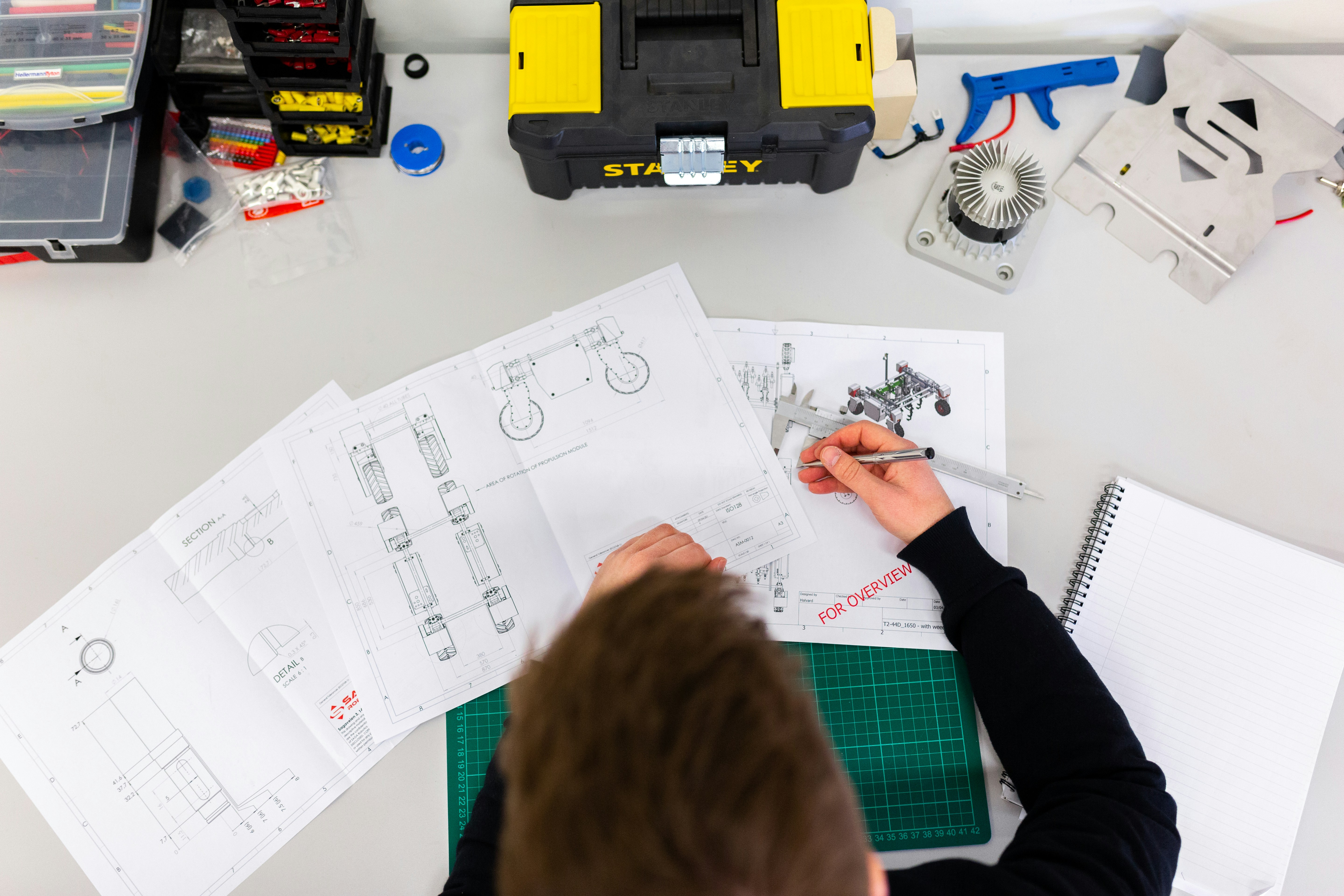

First, engage qualified personnel such as certified service engineers or a Radiation Safety Officer. X ray equipment disposal should never be carried out by untrained staff.

Power Down and Discharge

Second, fully power down the equipment and safely discharge all high-voltage components. This eliminates electrical hazards during dismantling.

Disable Radiation Components

Third, dismantle the X-ray tube and permanently disable radiation-producing components. This is the most critical step in the disposal of x ray machines.

Segregate Materials

Fourth, segregate materials. Lead shielding, oils, electronics, and metals must be separated into appropriate waste streams.

Transfer to Licensed Facilities

Finally, transfer all components to licensed recyclers or disposal facilities and retain documentation proving lawful x ray disposal.

Hazardous Materials in X Ray Equipment Disposal

X ray equipment disposal often involves hazardous substances that require special handling.

Lead

Lead is commonly found in shielding and tube housings. It must be recycled or disposed of as hazardous waste.

Beryllium

Beryllium windows in X-ray tubes are highly toxic and must be sealed and handled by specialists.

PCB-Contaminated Oils

Older equipment may contain PCB-contaminated oils, which require testing and licensed incineration.

Heavy Metals

Electronic components may include mercury or cadmium, which must be processed through approved e-waste channels.

These risks are why xray disposal cannot be treated as ordinary recycling.

Environmental Responsibilities in X Ray Disposal

X ray disposal is not just a radiation issue. Environmental protection is equally important. Improper disposal can contaminate soil and water and breach EPA regulations.

Best practice for x ray equipment disposal includes maximising recycling, minimising landfill, and maintaining full traceability of all waste streams. Hospitals and clinics are expected to demonstrate environmental due diligence alongside radiation safety compliance.

Certified X Ray Disposal and Recycling Options

There are several compliant pathways for x ray disposal in Australia.

Manufacturer Take-Back Programs

Manufacturer take-back programs are often the safest option.

Licensed Medical Equipment Recyclers

Licensed medical equipment recyclers specialise in x ray machine disposal and provide full documentation.

Accredited E-Waste Recyclers

Accredited e-waste recyclers can process electronic components once radiation risks are neutralised.

General Scrap Dealers

General scrap dealers should never be used unless all hazardous and radiation-related components have been removed and documented.

For compliant services, see internal guidance on medical equipment recycling: Medical Equipment Recycling Services Australia

For regulatory guidance, refer to ARPANSA.

Frequently Asked Questions About X Ray Disposal

Is x ray disposal legal in Australia?

Yes, x ray disposal is legal when the equipment is rendered permanently inoperable and handled in line with ARPANSA and state regulations.

Can parts of an X-ray machine be recycled?

Yes, once radiation-producing components are neutralised, metals, electronics, and lead can be recycled through certified channels.

Do I need to notify regulators when disposing of x ray equipment?

In most states, yes. Notification is a standard condition of radiation licences.

What is the biggest mistake organisations make with x ray disposal?

Using unlicensed scrap dealers or failing to document the disposal process.

Final Thoughts on X Ray Disposal in Australia

X ray disposal in Australia is a serious responsibility that demands planning, expertise, and strict compliance. Whether you are managing a hospital, dental clinic, veterinary practice, or laboratory, the principles are the same: permanently disable the equipment, manage hazardous materials correctly, document every step, and notify regulators.

Handled properly, x ray equipment disposal protects people, preserves the environment, and keeps your organisation on the right side of the law in 2026 and beyond.

How to Recycle Medical Devices in Australia: A Practical 2025 Guide

Across Australia, healthcare providers are under increasing pressure to manage outdated, unused, or end-of-life medical equipment responsibly. What was once considered a back-office task is now a strategic issue involving compliance, data security, sustainability, and public trust.

This guide explains how to recycle medical devices in Australia using practical, regulation-aligned methods that reflect how hospitals, clinics, and laboratories actually operate in 2025.

Table of Contents

Why Responsible Medical Device Recycling Matters

Improper disposal of medical devices exposes healthcare organisations to environmental harm, regulatory penalties, and operational risk. Many devices contain lithium batteries, heavy metals, and electronic components that cannot enter general waste streams.

Beyond environmental considerations, modern medical equipment often stores sensitive patient or operational data. Responsible recycling therefore plays a direct role in governance, risk management, and regulatory compliance.

Medical Device Disposal Regulations in Australia

Medical device disposal is governed primarily at the state level through Environmental Protection Authorities (EPAs). Requirements vary between jurisdictions such as NSW, Victoria, and Queensland, particularly around licensing and documentation.

Healthcare facilities must ensure that any recycling or disposal partner is authorised to process regulated medical and electronic waste and can provide full chain-of-custody records.

Medical Equipment Recycling Options

Electronic & Diagnostic Equipment

Patient monitors, imaging systems, infusion pumps, and laboratory analysers often qualify for recycling after decontamination and secure data destruction.

Surgical Instruments & Clinical Tools

The appropriate way to dispose of surgical instruments depends on their condition and contamination status. Reusable metal instruments are typically sterilised and recycled through licensed metal recovery channels, while single-use or contaminated tools require controlled disposal.

Laboratory & Research Equipment

Centrifuges, microscopes, and analytical instruments contain recoverable materials alongside hazardous components. Specialised recycling processes are essential to manage these safely.

Reuse, Donation & Surplus Medical Equipment

Not all unwanted medical equipment needs to be dismantled or destroyed. A significant portion of surplus assets can be safely reused, refurbished, or donated if they remain functional and meet current safety standards.

In systems such as the NHS, unwanted equipment is typically assessed for redeployment within the healthcare network before being offered to approved charities or refurbishment programs. In Australia, similar principles apply through licensed reuse pathways.

Medical equipment that can be reused includes durable medical equipment, mobility aids, non-invasive diagnostic tools, and certain laboratory devices. Reuse must always occur within regulated frameworks to ensure patient safety and traceability.

Most Effective Methods of Medical Waste Disposal

The most effective method of disposing of medical waste depends on the waste classification. General medical waste, sharps, contaminated devices, and electronic equipment each require different handling.

High-risk or biohazardous waste is typically treated through high-temperature incineration or approved sterilisation processes. Electronic medical waste should be processed through licensed e-waste recyclers to ensure environmental protection and material recovery.

Frequently Asked Questions

What can I do with unwanted NHS equipment?

Unwanted NHS equipment is usually assessed for internal reuse first. If no longer required, it may be refurbished, donated through approved programs, or processed through licensed recycling facilities depending on condition and regulatory requirements.

How should surgical instruments be disposed of?

Reusable surgical instruments are typically sterilised and recycled through metal recovery programs. Single-use or contaminated instruments must follow controlled clinical waste disposal pathways.

What medical equipment can be reused?

Durable medical equipment, non-invasive diagnostic devices, mobility aids, and some laboratory instruments can often be reused if they remain functional, safe, and compliant with current standards.

What is the most effective method of disposing of medical waste?

The most effective disposal method depends on the waste category. High-risk medical waste requires specialised treatment, while electronic equipment should be recycled through licensed processors to ensure environmental and regulatory compliance.

Need Expert Support?

Professional assessment ensures compliance, reduces environmental risk, and supports responsible medical equipment lifecycle management.

Speak with a Medical Recycling Specialist